CHJ-D Paper lunch box forming machine (MECHANICAL) is an ideal choice that adopts a mechanical driving system to produce lunch boxes, takeaway noodle boxes, and food trays.

Whatsapp:

+8617838313982E-mail:

[email protected]The paper lunch box-making machine is a kind of mechanical equipment used to make paper lunch boxes. The paper lunch box forming machine adopts advanced technology and an automation system, which can produce a large number of lunch boxes in a short time. Its design and features are designed to increase the productivity and quality of lunch boxes while reducing labor costs and environmental impact. This is very beneficial for restaurants, fast food restaurants, and other establishments that require a large number of meal boxes.

1. The hot wind blow from the heating tube, which makes the PE-coated papers stick together more tightly.

2. Besides the mechanical system, the machine on one line produces very fluently: paper feeding, heating, forming, pulling out, and collecting heating. So the machine speed can double.

3. The CHJ-D Paper lunch box forming machine is controlled by a mechanical system, with no need air compressor. It saves our customers at least 6 KW of power when the machine is running.

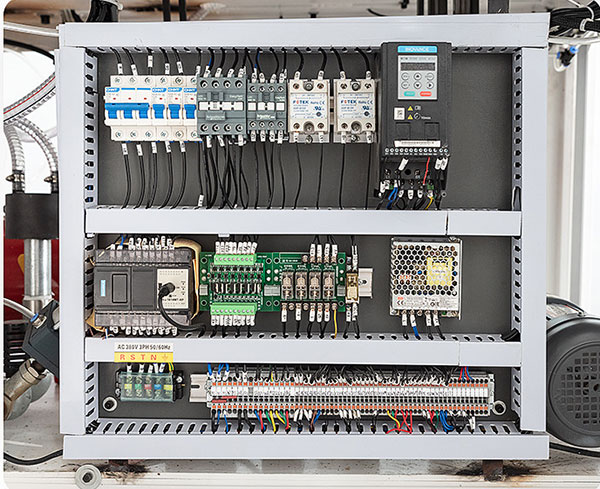

Electronic control system brand accessories

High stability innovative PLC control system and Schneider brand electrical components, reliable quality, and easy maintenance;

Smart touchscreen operation is simple and convenient

Using PLC controller, touch screen. All working parameters can be set on the control panel, which is convenient for parameter setting and adjustment;

Manipulator design

With the use of manipulators, the picking accuracy of finished cartons is higher, and the cartons can be correctly unloaded into the collection and storage unit;

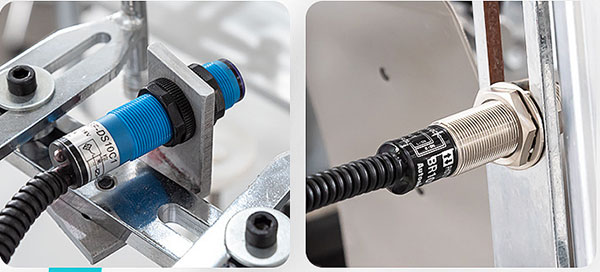

Sensor Fault Self-Test

Automatic detection of sensor failure, it will automatically stop working when there is a failure, which greatly improves safety, and the error information will be displayed on the PLC touch screen;

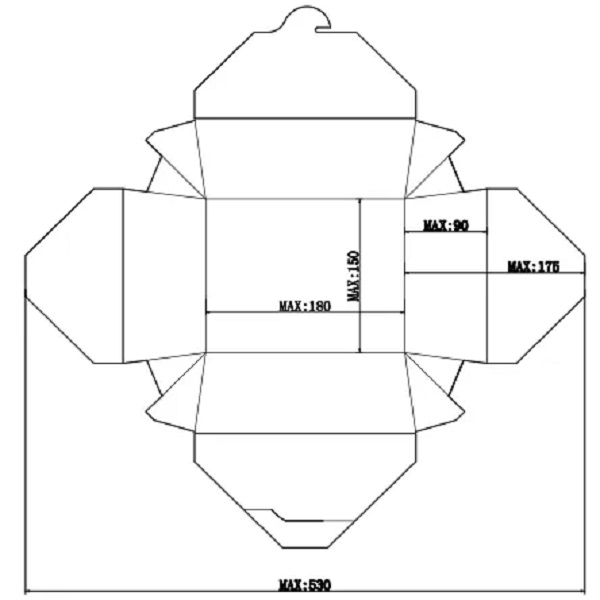

| Type | CHJ-D 60 | CHJ-D 120 |

| Max Forming Depth | 60mm | 120mm |

| Production capacity | 30-45pcs/min | 30-40 pcs/min |

| Suitable Material: | 200–400g/m2

single or double PE-coated paper |

|

| Total Power: | 4KW | 6KW |

| Total Weight: | 1250KGS | 1750KGS |

| Overall Dimension: | 2200 x1100×1700 mm | 2800 x1100×1700 mm |

| power source | 380V 50HZ | |

Here is the paper lunch box-making machine youtube video of the paper lunch box manufacturing process for your reference!!

1. Hot air generator

Stable heating, good sealing quality, no leakage;

2. powerful generator

Faster speed, more stable;

3. High-quality cam

Stronger and more durable;

4. Blower and air tank

Hot air source, more conducive to carton sealing;

In a word, the paper lunch box forming machine is a kind of efficient, high-quality, and environmentally friendly mechanical equipment. It can not only improve the production efficiency and quality of lunch boxes but also reduce labor costs and environmental impact. With the continuous development of the catering industry, the paper lunch box forming machine will be more widely used in the future.

If you need our products please write down any questions, we will reply as soon as possible.