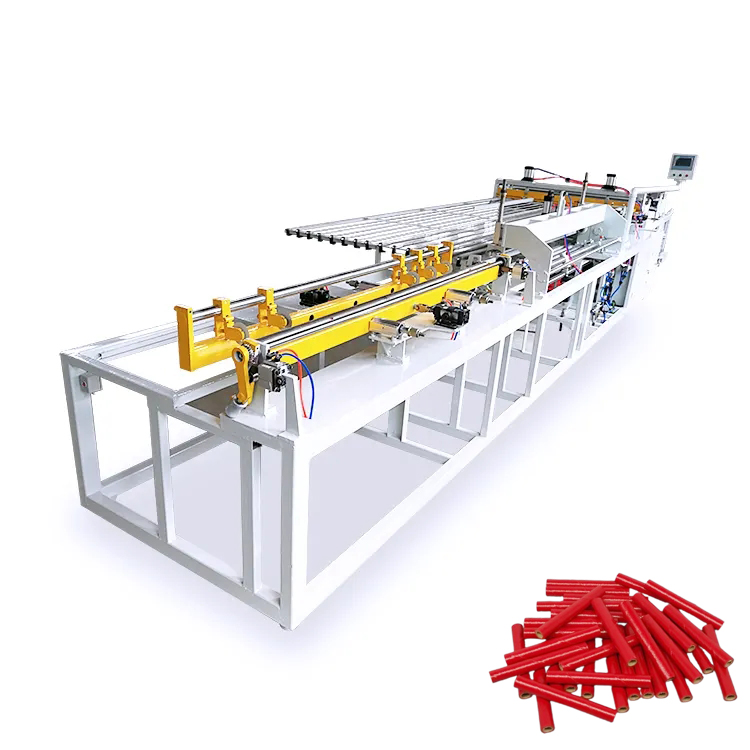

Fireworks paper tube making machine is also called parallel paper tube making machine. This paper tube machine is specially developed for the production of fireworks and firecrackers.

Whatsapp:

+8617838313982E-mail:

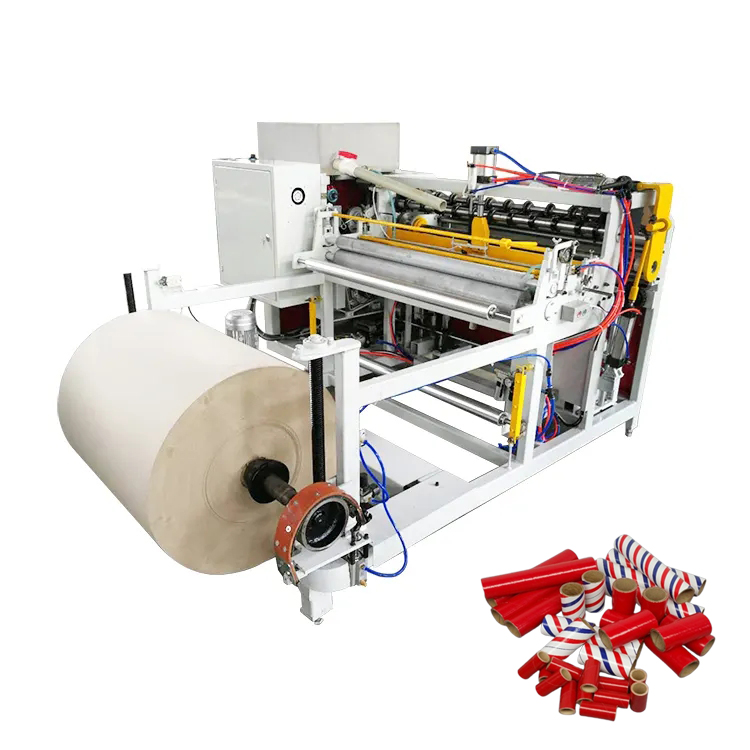

[email protected]Fireworks paper tube making machine is also called parallel paper tube making machine. This paper tube machine is specially developed for the production of fireworks and firecrackers. The flat rolling paper tube machine is suitable for making paper tubes with small inner diameter, high wall thickness and density. During the production process, a layer of waterproof tissue is automatically added to the surface, which can protect the fireworks from moisture during storage and extend the shelf life of the fireworks. Moreover, the fireworks and firecrackers produced by this paper tube machine are stronger and denser, reducing safety hazards.

The fireworks paper tube machine working principle is to feed the paper roll into the machine through the paper roll device, cut it through the cutting device, and then roll the paper roll into a tube shape through the tube rolling device. After the fireworks paper tube making machine is started, the large roll paper successively passes through the ten major systems of the braking system, the smoothing system, the gluing system, the even gluing system, the paper feeding system, the deceleration system, the paper cutting system, the paper feeding system, the tube rolling system, and the tube pushing system. Finally, a high-quality flat roll fireworks paper tube is made. The entire process takes 2-3 seconds at the fastest and requires no manual control. The entire process is controlled and monitored by the control system to ensure the stability and accuracy of the production process.

| Model | QZD-1250 | QZD-1600 | QZD-2000 | QZD-3000 |

| Input power | AC380±10% 50Hz | |||

| Pulley servo motor | 380V 3KW 2000R/Min | |||

| Tube reel servo motor | 380V 3KW 2000R/Min | |||

| Paper feed motor | 1.5KW 4 poles | 1.5KW 4 poles | 1.5KW 4 poles | 1.5KW 4 poles |

| Paper edge grinding motor | 1.5KW 2 pole | 1.5KW 2 pole | 1.5KW 2 pole | 1.5KW 2 pole |

| Dust removal fan motor | 1.5KW | 1.5KW | 1.5KW | 1.5KW |

| Paper lifting motor×2 | 1.1KW | 1.1KW | 1.1KW | 1.1KW |

| Total power | 13.5KW | 13.5KW | 13.5KW | 13.5KW |

| Enter air pressure | >0.6MP | |||

| Gas flow | 2³m/h | 2³m/h | 2³m/h | 2³m/h |

| Processing length | 700mm | 1600mm | 2000mm | 3000mm |

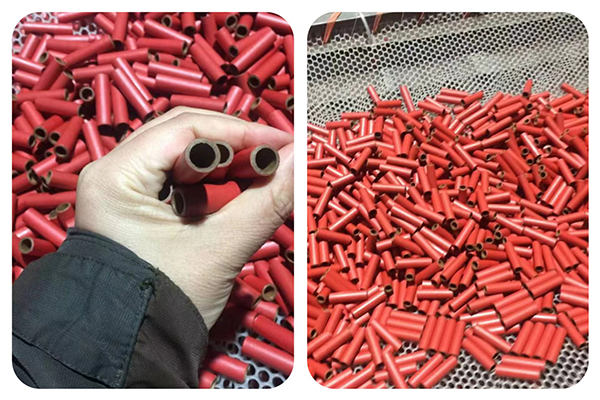

The paper tube produced has high compactness (porcelain solid), high burning resistance, high inter-layer bonding force, and no bubbles between layers;

You can directly use the original large roll paper from each paper mill, and the base paper can be directly processed into a flat roll paper tube without secondary processing;

The segmented upper and lower plates are different from the previous whole-section upper and lower nip rollers. It is easy to adjust the direction of the paper during the tube rolling process, so that the paper can be rolled from the middle to both sides. The produced paper tubes are straight, not folded, and have good burn resistance. High density (porcelain solid) and high strength;

In general, the fireworks paper tube machine is an indispensable and important equipment in the fireworks manufacturing industry. It can help manufacturers improve production efficiency, ensure product quality, and improve safety. With the continuous advancement of technology, our fireworks paper tube machines are also constantly innovating and developing, bringing more convenience and opportunities to the fireworks manufacturing industry. If you are also interested in fireworks paper tube machine, please feel free to leave a message with us online to get more detailed information and free quotation about fireworks paper tube machine!!

If you need our products please write down any questions, we will reply as soon as possible.