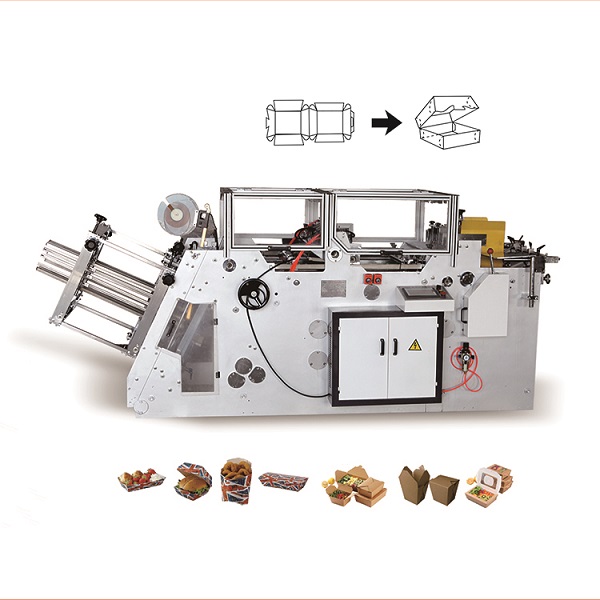

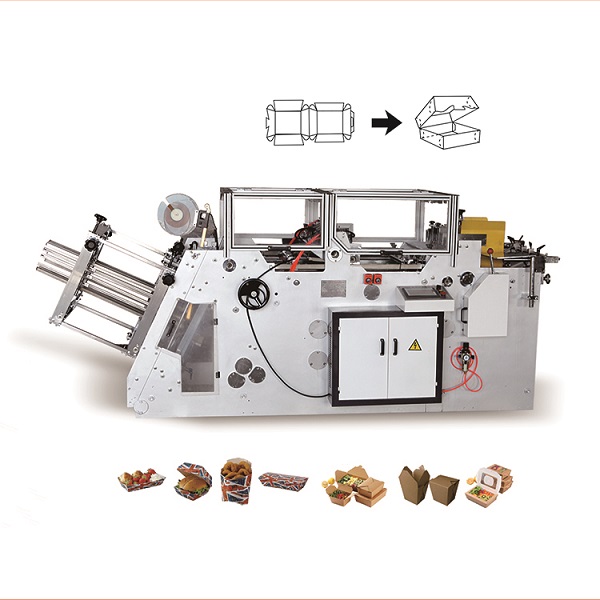

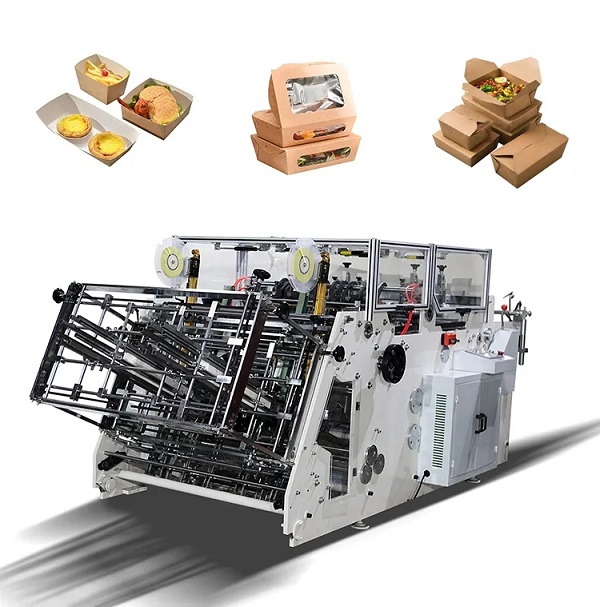

HBJ-D800 Carton erecting machine is an ideal choice to produce hamburger boxes, French fries boxes, food trays, lunch boxes, Chinese noodle boxes, hot dog boxes, etc. It adopts a micro-computer, PLC, alternating current frequency converter, vacuum-sucking paper feeding, auto gluing, automatic paper tape counting, and chain drive.

Whatsapp:

+8617838313982E-mail:

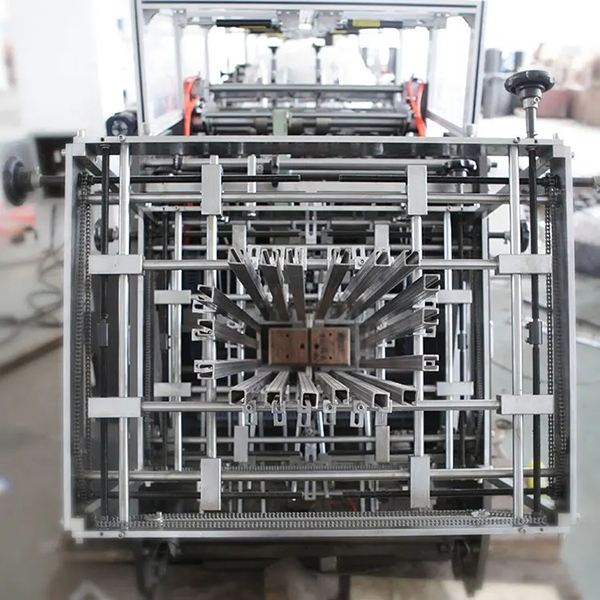

[email protected]The automatic carton erecting forming machine directly forms the three-dimensional paper by stamping, it not only can hold solid or liquid food but also subtracts the action of opening the lunch box processed by the traditional box-gluing machine, but also greatly shortens the food boxing time and satisfies the environmental protection, sanitation, sealing, and fast circulation and other fast food requirements for packaging boxes. The carton-forming machine conforms to “CE” certification and also has the features of accurate and stable transmission, high production efficiency, and a small footprint.

On the same machine, more than 10 different types and specifications of lunch boxes, French fries boxes, three-dimensional boxes, hamburger boxes, and other products can be manufactured just by changing the mold.

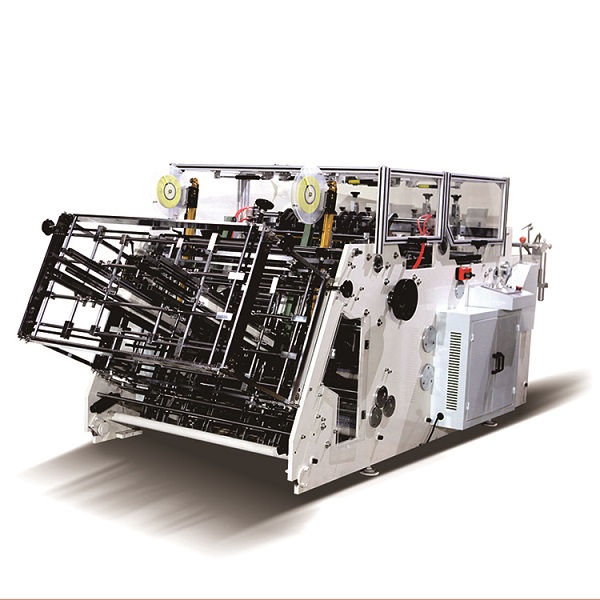

Height adjustable;

Strong and strong;

Thickened fuselage;

High work productivity;

Fast box making/wide range;

Simple design, easy operation;

The large motor delivers smoothly;

High configuration of electrical components;

| Type | HBJ-D800 | HBJ-D1200 | HBJ-D2000 |

| Production capacity | 50-180 pcs/min | 80-320pcs/min | 100-300 pcs/min |

| Suitable Material: | 200-600g/m2 card paper, PE coated paper, kraft paper, corrugated paper | ||

| Length: | L100-450mm,degree:5°-40°

|

L100-450mm,degree:5°-40° | L100-450mm, degree:5°-40° |

| Width: | 100-600mm | W100-400mm | B100-600mm |

| Hight: | 15-200mm | H15-200mm | H15-200mm |

| Total Power: | 5KW | 6.25KW | 3KW |

| Total Weight: | 1.8T | 2.8T | 2.2T |

| Overall Dimension: | 3600 x1400 x 1700 mm | 3600 x 1850 x 1700 mm | 2300 x2200 x 2100 mm |

| power source: | 380V /220V 50HZ | 380V 50HZ | 380V 50HZ

|

Here is the paper carton erecting forming machine youtube video working process in our factory for your reference!!

Carton forming

It can be adjusted according to different carton styles and sizes to produce various types of cartons;

PLC+ man-machine interface screen control

Complete the packaging processes such as carton output, paper feeding, gluing, forming, and collection at one time;

Carton rack

The stainless steel tube collection method is adopted, and the paper feeding can be replenished at any time without stopping;

Touch screen control panel

Graphical interface, easy to operate, convenient to adjust parameters and settings, saving manpower and material resources;

Electrical components

The high-power motor, strong power, large bearing capacity, fast and stable operation and transmission, and accurate control;

If you also have any carton or box shape forming requests, welcome to contact us freely to send us your carton or box shape pics and W*X*H parameters, and we can recommend the suitable carton erecting forming machine types according to your specific request and send you the 100% free quotation online!!

If you need our products please write down any questions, we will reply as soon as possible.