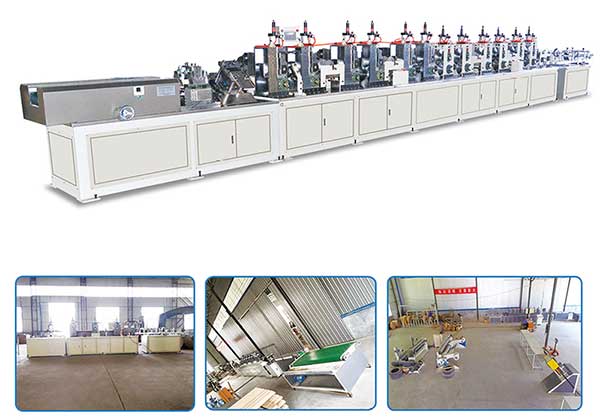

JYD-H40 paper edge protector machine is suitable for the production of paper angle protectors with a width of 25-100mm and a thickness of 2-8mm.

Whatsapp:

+8617838313982E-mail:

[email protected]The JYD-H40 paper edge protector machine can produce a paper corner protector with bobbin paper and kraft cardboard, and the two ends are smooth and flat, without obvious burrs, and perpendicular to each other. The produced paper corner protector has a width of 25-100mm and a thickness of 2-8mm, which is used to strengthen the corners of packaging cartons.

Paper corners are also called paper channel steel, paper corners, corner boards, corner strips, paper angle irons, paper corner strips, corner cardboard, edge-wrapping boards, corner paper, and paper angle steel, and are widely used in electronic appliances, high-tech products, furniture, and other products packaging and transportation.

1. Eight sets of pressure rollers;

2. The maximum speed can reach 40 m/min;

3. Servo tracking cutting, any order length can be set;

4. There are four types of JYD-H40 High speed CNC angle protector machine, corner protectors + punching (flushing or ring), corner + flat, and corner + punching (flushing or ring) + flat.

Here is the paper edge protector machine youtube video working process in our factory for your reference!!

| Technical parameter | |

| Paper Angle Protection Specification | Wide20-100mm |

| The thickness of the plate | Long50-9000mm |

| Control method | Thick2-8mm |

| Production speed | 0-40m/min |

| paper layers | 12layers |

| Forming roller | 8 groups |

| way to control | Frequency |

| Cut off method | Automatic CNC cutting |

| Number of operators | 1-2 |

| total weight | 4590kg |

1. This angle protector machine has a wide range of requirements for paper specifications;

2. Imported servo system, hydraulic cutting device, high cutting precision, can cut with multiple knives;

3. The product specification can be set arbitrarily, and the specification change is convenient and quick;

4. A variety of gluing methods are optional for users, with a controllable heating system, even gluing and smooth wrapping;

5. The operation of the man-machine interface is simple and convenient, and only 2-3 people are needed for the whole machine;

6. Eight sets of cylinder pressures are used to control the synchronous pressure rollers to ensure uniform speed and pressure, effectively avoiding wrinkles and damage to facial tissue;

If you need our products please write down any questions, we will reply as soon as possible.