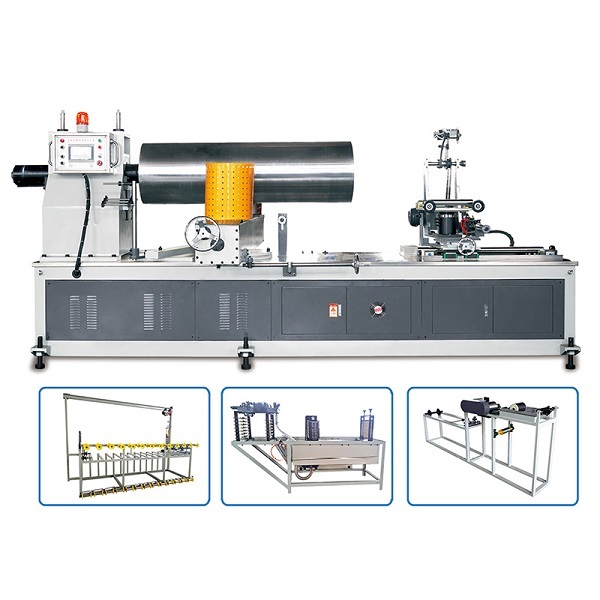

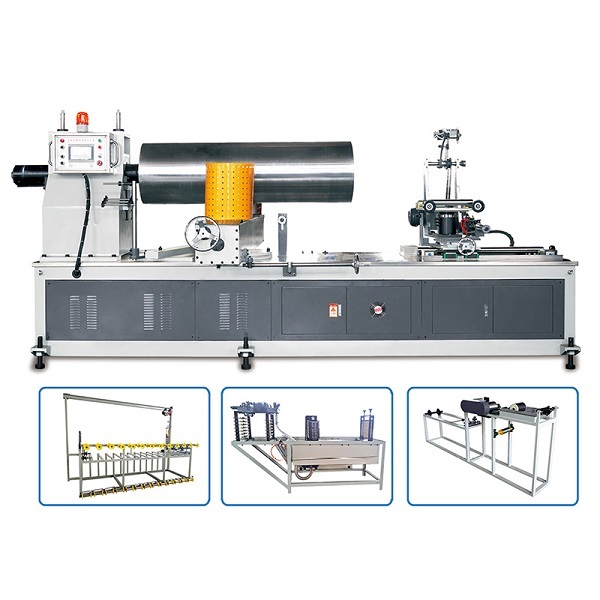

JYD-JG350A Two-head CNC paper tube machine is suitable for the production of various industrial paper tubes such as tapes, webs, chemical fiber tubes, packaging paper cans, etc.

Whatsapp:

+8617838313982E-mail:

[email protected]The spiral paper core tube-making machine with 2 heads is specially designed to produce 1-8(mm)thickness, 50-350(mm)inner diameter paper tubes/paper cores, with high efficiency, precision, and stability features.

Suitable for the production of various types of paper tubes and cans, such as packaging cans, tea cans, food cans, wine cans, fireworks tubes, calendar tubes, fax paper, plastic wrap, toilet paper cores, etc.

The spiral paper tube machine’s working principle is to use the two heads to rotate at the same time to roll the paper into a spiral shape bond it, and finally form a paper tube. This working principle enables the paper tube machine to produce paper cores efficiently, and the diameter and length of the paper tubes can be adjusted as needed to achieve production flexibility.

Here is the automatic paper tube-making machine with 2 heads working process in our factory for your reference!!

1. CNC servo cutting device, high-precision cutting;

2. Computer PLC control, touch screen human-machine interface operation;

3. Stainless steel glue basin, polyurethane glue knife, and high carbon steel glue knife are durable;

4. The round knife automatically cuts, making the cut smoother and the performance more stable;

5. Automatic cutting and automatic pipe drop, automatic speed change, and automatic recovery during cutting;

6. Integrated paper rack and glue supply system, paper guide integrated linkage device, fully electric adjustment;

7. Equipped with a multi-functional bottom paper waxing device and automatic shutdown function when the paper is out of stock;

| Technical parameter | |

| Paper layer | 2-12layers |

| Inner diameter | 50-350(mm) |

| Thickness | 1-8(mm) |

| Speed | 0-25(m/min) |

| Fixed length mode | Numerical control (light control) |

| Winding head | Two head |

| Cutting method | Circular knife CNC automatic |

| Gluing method | Double-sided glue |

| way to control | Numerical control |

| Input voltage | 380V/220V |

| Number of operators | 1-3 |

| Total weight | 3736kg |

| Core winding die fixing | Flange |

| Mandrel | 1 |

| Tube belt | 1Pieces |

| Unloading rack | Stainless steel automatic |

| Application tools | 1 set |

1. The transmission part has no chain or sprocket and is designed to be ultra-quiet, eliminating the trouble of replacing chain gears;

2. Use double-sided glue an independent stainless steel glue tank and an imported polyurethane scraper to produce paper tubes with stronger strength;

3. The single circular knife cutting design imported from Germany makes the paper tube incision smoother, eliminating the need for precision cutting and waste;

4. Cutting is always accurate and waste-free at any speed, which is an incomparable advantage of traditional electromagnetic speed-adjustable paper tube machines;

5. The main motor adopts an imported PLC logic control system and adopts frequency converter for speed regulation, which saves 50% of electricity compared with ordinary electromagnetic speed regulation;

Overall, the double-head design of the spiral paper tube forming machine brings many benefits to the paper tube manufacturing industry. It improves production efficiency, reduces labor costs, increases production flexibility, and improves the stability of the production line. Therefore, this kind of machine has a very important position in the paper tube manufacturing industry and will continue to play an important role.

If you need our products please write down any questions, we will reply as soon as possible.