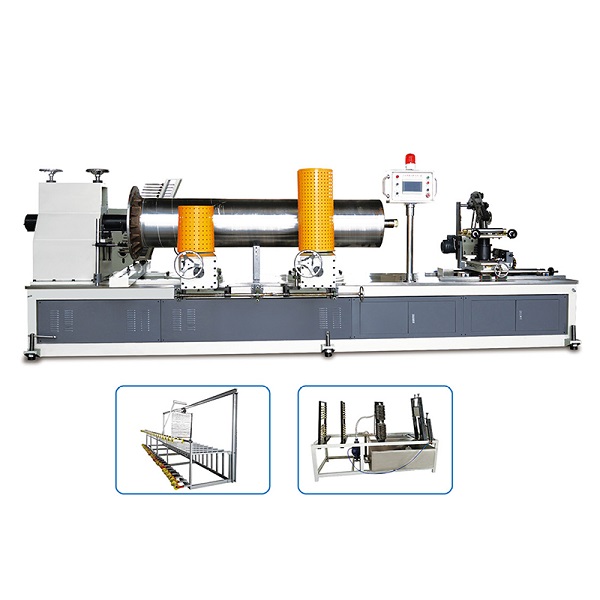

JYD-JG500 4-head paper tube machine is used for producing paper tubes, it can roll paper into cylindrical shapes for packaging, transportation, and storage. The 4 heads paper tube-making machine with 4 heads can make thicker paper tubes and have higher paper core production efficiency!! It is mainly used for tubes for steel strips, tubes for stainless steel plates, films, tubes for printing and paper making, etc.

Whatsapp:

+8617838313982E-mail:

[email protected]A 4-head paper tube machine is a machine used for producing paper tubes, it can roll paper into cylindrical shapes for packaging, transportation, and storage. The 4 heads paper tube-making machine with 4 heads can make thicker paper tubes and have higher paper core production efficiency!!

1. Compared to the 2-head paper tube machine, the paper tubes it produces are not only thicker but also more efficient.

2. By using a 4-head paper tube machine, manufacturers can meet customer needs more quickly and accurately, enhancing competitiveness.

3. 4 A head paper tube-making machine is the equipment used for producing paper tubes, which has the characteristics of high efficiency, accuracy, and stability.

| Paper Tube machine parameter | |

| Number of paper layers | 3-25layers |

| Paper tube diameter | 76-500(mm) |

| The thickness of the paper tube | 2-15(mm) |

| Main power | 30KW |

Here is the large paper tube-making machine testing in our factory for our Ecuador customer for your reference!!

Safety protection notice

Please be sure to read the letter to the user, the instructions for the use of the machine before (especially special precautions stated in the book), master boot right, and before boot operation.

1. When the machine is running, no moving parts reach any machine (especially the belt).

2. The environment around the machine should be clean, tidy, and suitable for the light so that no other sundries can be placed nearby to avoid inconvenience to the operator.

3. Before starting the machine, it is necessary to ensure that the screws of the moving parts of the machine are firmly connected.

4. The power supply must be cut off before maintenance.

5. Voltage, motor, and parts with high-voltage terminals and other parts do not contact, to avoid the risk of electric shock.

6. million do not use wet hands to touch the switch, otherwise, it will cause an electric shock.

7. In the installation of fuses, the JYD-JG500 Four-head CNC paper tube machine must be cut off.

8. There should be a separate grounding wire, the length should be as short as possible.

9. The rest of the note, here is not a narrative, we explain it in the instructions.

Must be regular to the chain, gear, shaft, and other parts needed to lubricate the lubricating oil and grease, to ensure the safety and service life of the equipment.

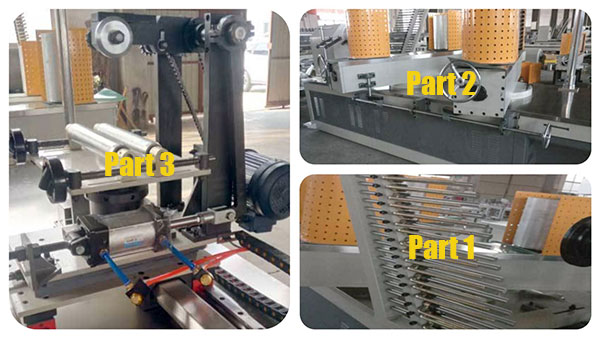

There are three main parts, the first part of the paper tube-making machine is a paper holder, the second part is a Paper roll machine, and the third part is a cutting machine.

I. The main part of the coil

Used to distribute the strips of the coiled tube on the input tray as required.

Roll the paper coming from the paper tray into the desired paper tube.

II. Control panel section

Used to operate the equipment coil start and stop and speed.

III. Pipe cutting section

JYD-JG500 Four-head CNC paper tube machine is used to divide the rolled paper tube into equal segments by size.

IV. Distribution box part

Used to configure the original control of the whole machine.

1. CNC and servo cutting device, with high cutting accuracy;

2. Round knife cutting, smoother incision, and more stable performance;

3. Computer PLC control, touch screen human-machine interface operation;

4. Automatic cutting, automatic pipe dropping, automatic transmission, and automatic recovery;

We are a professional paper tube machine manufacturer. These paper tube machines are typically used to produce products such as paper tubes, paper cores, and paper tube cores. We have advanced production technology and equipment, which can provide high-quality products and professional after-sales service. All paper tubes can be specially manufactured according to your actual production situation, so please provide us with detailed information about your paper tubes: outer diameter, inner diameter, wall thickness, maximum and minimum cutting length, number of layers (or paper thickness), which product to use, any special requirements, etc. Our engineers and sales personnel will quickly develop the best solution for you. In addition to paper tube manufacturing machines, we also provide large groove paper slitting machines and paper tube cutting machines. If you need more information about these machines, please contact us or send us an inquiry online freely!!

If you need our products please write down any questions, we will reply as soon as possible.