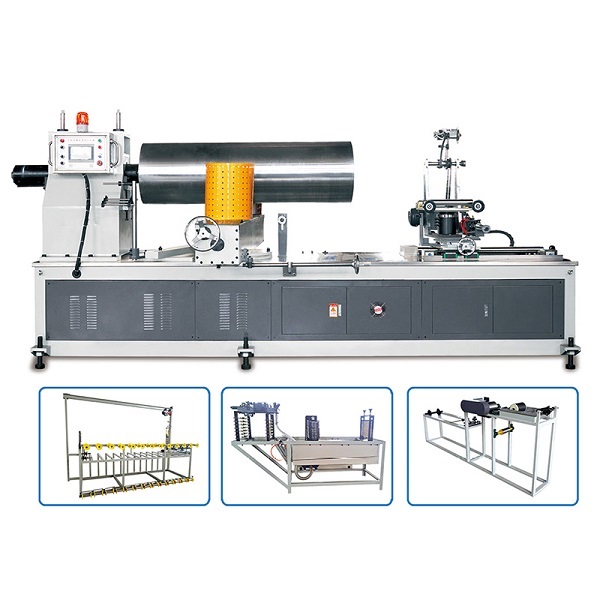

JYD-JG600A paper core tube making machine is mainly used for the production of large-diameter thin paper tubes such as steel strips and stainless steel plates.

Whatsapp:

+8617838313982E-mail:

amandajones1324@gmail.comJYD-JG600A paper core tube making machine is mainly used for the production of large-diameter thin paper tubes such as steel strips and stainless steel plates.

1. The mold is fixed by flange and female-female buckle, which is easy to replace.

2. The main engine adopts electric angle adjustment, which is convenient to operate;

3. The high degree of automation reduces the labor intensity of workers and improves production efficiency.

4. JYD-JG600A Two-head CNC paper tube machine the cutting table is equipped with a servo synchronous circular knife for cutting so that the gap between the paper tubes is uniform and the cutting end surface is flat;

Here is the paper tube-making machine youtube video working process in our factory for your reference!!

| Technical parameter | |

| Number of paper layers | 3-15layers |

| Paper tube diameter | 76-650(mm) |

| The thickness of the tube | 2-10(mm) |

| Main power | 30KW |

| Input voltage | 380V/220V |

| Number of operators | 1-3 |

| Total weight | 5100kg |

1. Low noise transmission design;

2. Adopt a PLC logic control system;

3. Low price, strong versatility, and high-performance configuration;

4. Modular electrical layout design, more convenient and scientific maintenance;

5. The main motor adopts a vector-type high-torque frequency converter for speed regulation;

6. Independent stainless steel tank with double-sided glue is used, and an imported silicone tube is used for scraping glue;

7. It is more convenient to operate with the remote control (such as remote control stops or slow speed when the paper breaks);

8. Single photoelectric positioning length control, with automatic speed change function to make the paper tube cutting length more accurate;

If you need our products please write down any questions, we will reply as soon as possible.