Iron Hoop Fiber Drum Production Line is an automated production line dedicated to the production of iron hoop fiber drums, covering cardboard forming, drum body rolling, bottom sealing, hoop installation and other processes

Whatsapp:

+8617838313979E-mail:

[email protected]The Iron Hoop Fiber Drum Production Line has a reasonable structure, easy operation and high efficiency, and is suitable for the needs of chemical, pharmaceutical, food and other industries for medium and high strength packaging barrels. The entire line can be customized according to different specifications, with the characteristics of energy saving and environmental protection, high strength of finished products, beautiful and durable, and is an ideal equipment choice for the modern packaging industry.

The entire production line includes the following machines:

This machine can be used to roll round and square paper barrels. You only need to change the mold. There are two types: with automatic veneer and without veneer. The specifications are 820 and 1100, which can be customized according to actual production needs. The whole machine consists of a paper rack, a paper separation knife rack, a gluing device, a barrel rolling device, a paper cutting device, a barrel unwinding device, and a barrel receiving device. The paper shafts are all inflatable shafts, and the paper racks are automatically raised and lowered. PLC and inverter control, CNC adjustment.

Parameter

| Model | JYD-820 | JYD-1100 |

| Maximum jumbo roll diameter | 1300mm | 1300mm |

| Maximum jumbo roll width | 800mm | 1080mm |

| Square tube width range | 240-400mm | 240-400mm |

| Round tube diameter | 240-450mm | 240-450mm |

| Paper weight | 280-360gsm | 280-360gsm |

| Gluing method | Single layer | Single layer |

| Square tube produce speed | 150pcs/h | 150pcs/h |

| Round tube produce speed | 200pcs/h | 200pcs/h |

| Power | 10.5KW | 12KW |

| Weight | 2000kgs | 3000kgs |

| Dimension | 4200x2400x1500mm | 4220x2420x1500mm |

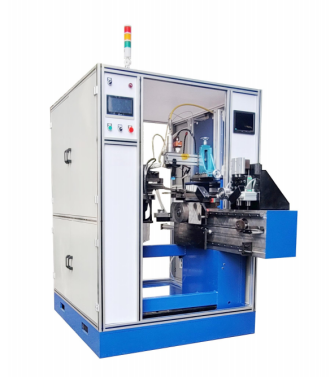

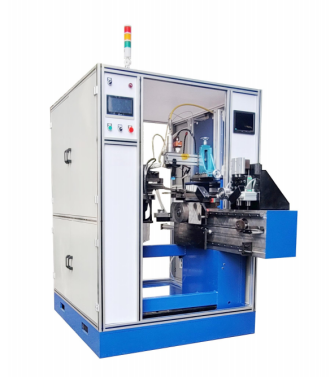

This equipment is mainly used for the cutting, welding and edge-beating of steel strips for iron hoop barrels (welding wire barrels).

Cutting, welding and edge-beating are integrated into one-step forming. The cutting diameter range is 270-650mm. The size can be switched at any time. The cutting width is 48-75mm (special specifications can be customized). The edge-beating width is adjustable. High efficiency: about 8 welds per minute. When the material is out of stock or the output is reached, the machine will automatically stop and wait. No special person is required. The whole machine has heavy-duty racks, chillers, lasers, laser heads, etc., PLC, inverter, servo motor control, CNC adjustment

Parameter

| Model | JYD-HJ |

| Welding width | 48-75mm |

| Capacity | 450pcs/h |

| Power | 6KW |

| Chiller | 745x610x1030mm |

| Rack | 1000x800x1050mm |

| Host size | 1900x1750x1950mm |

| Weight | 2000kgs |

| Area | 1.3x2m |

The overall structure of the machine is beautiful, solid and stable. The machine base is welded with 16MM thick steel plate, equipped with 35 linear slider, guide surface and motor mounting surface, and is processed and formed in one step by CNC gantry milling. It is equipped with automatic water spraying function, and the barrel mouth and barrel bottom are rolled at one time to ensure the rolling quality.

Parameter

| Model | JYD-NB |

| Diameter | 280-650mm |

| Height | 300-1100mm |

| Speed | 180pcs/h |

| Power | 8.5KW |

| Operator | 1 |

| Weight | 1600kgs |

| Area | 2×2.9m |

The machine base is welded with 16MM thick steel plates, equipped with 35 linear sliders, guide surfaces and motor mounting surfaces, and is formed in one step using CNC gantry milling. A special barrel feeding device is used to ensure stable and reliable barrel feeding. The machine heads on both sides are controlled separately, with dual oil pumps for oil supply, stable oil pressure, and can be started separately, with a lack of material recognition function.

Parameter

| Model | JYD-YF |

| Diameter | 280-650mm |

| Height | 300-1100mm |

| Speed | 240pcs/h |

| Power | 7KW |

| Operator | 1 |

| Weight | 2600kgs |

| Area | 2×3.5m |

Computer control, safe and simple operation, convenient and fast length adjustment, automatic counting and statistics, no need for personnel on duty after automatic operation mode, the product has a smooth appearance, rounded interface, and an overall beautiful appearance. Punching can be riveted or welded. The punching position and aperture size can be customized according to customer requirements. Equipped with an electric feeder

Parameter

| Model | JYD-ZG |

| Diameter | 280-650mm |

| Speed | 360pcs/h |

| Power | 3KW |

| Operator | 1 |

| Weight | 900kgs |

| Area | 1.8×4.3m |

Features: The machine is small and lightweight; it uses air pressure as power and is easy to operate! Automatic rivet feeding and high riveting efficiency! It takes up little space, is easy to move, and is suitable for assembly line operations;

Usage: Used for riveting very small rivets on shelves, circuit boards, mica sheets, electronic products, hairpins, keychains, badminton rackets, umbrella frames, etc.

Parameter

| Model | JYD-CK |

| Rivet diameter | 0.3-0.8mm |

| Rivet length | 2.0-25mm |

| Height | 60mm |

| Speed | 1800-3600pcs/h |

| Power | 1/80hp |

| Operator | 1 |

| Weight | 175kgs |

| Dimension | 600*600*1850mm |

If you need our products please write down any questions, we will reply as soon as possible.