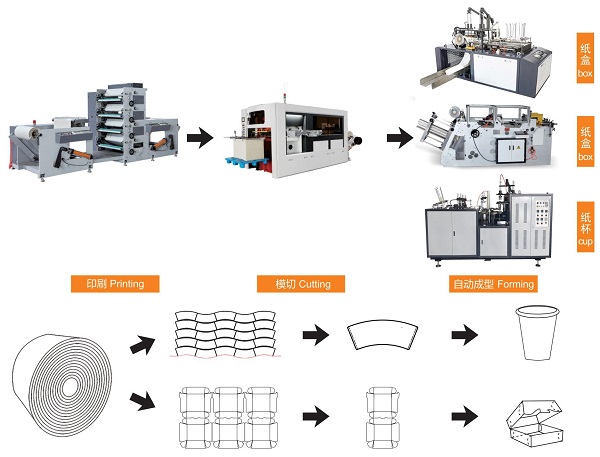

The design of the OCM-12 Paper cup machine can shorten the stroke of the machine. It can achieve fast operation and stable performance. It is suitable for paper ranging from single PE to double PE, 200g to 400g paper.

Whatsapp:

+8617838313982E-mail:

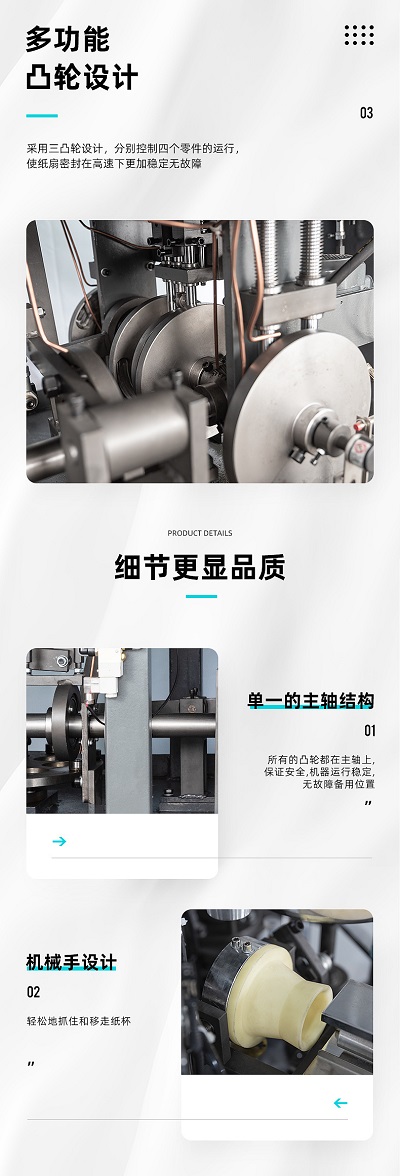

[email protected]OCM-12 Paper cup machine adopts an open intermittent indexing mechanism, gear transmission, and longitudinal axis structure, so as to reasonably distribute various functional assemblies. The whole machine is lubricated by oil to reduce the wear of machine parts; the cup wall is first heated by ultrasonic waves to ensure stable bonding, and the bottom of the cup is bonded by a heater for secondary crimping, the first is rotating crimping, and the second is heating shaped to improve the forming strength of the paper cup, beautiful roll mouth, and stable size.

1. Hot air heating on both sides of the bonding can improve the bonding effect of the cup wall and reduce the water seepage rate;

2. 90-degree rotating cup feeding. Make each formed paper cup 100% sent to the mold, reducing the waste caused by feeding the cup;

3. One-time delivery of the bottom of the cup. The bottom of the cup is sent into the cup at one time, with high accuracy and less waste from secondary bottom delivery;

4. Rotate the bottom of the roll. Reduce the printing abrasion on the surface of the bottom of the cup, and the bottom of the roll is even, without damaging the printed surface and the bottom of the double PE cup;

5. Count out the cups set 50 cups to be placed automatically;

6. OCM-12 Paper cup machine the body parts of the machine are finished, and each part is guaranteed to be interchangeable.

If you need our products please write down any questions, we will reply as soon as possible.