Paper Tube Machine Production Process

The spiral paper tube machine is a kind of equipment specially used for producing spiral paper tubes, which is widely used in packaging, textile, printing and other industries. The production process usually includes the following steps:

Paper winding

Put the base paper (usually kraft paper or other tough paper) on the unwinding rack and adjust the tension to ensure smooth paper transportation.

Gluing

The base paper is glued through the glue tank. Commonly used glues are water-based glue or hot melt glue to ensure that the paper layer can be firmly bonded.

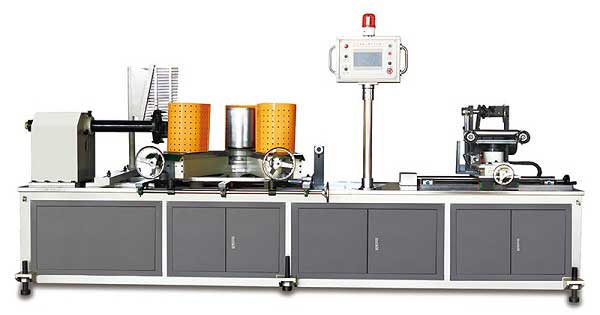

paper tube machine

Wrapping

The glued paper enters the winding forming device and is wound into a paper tube in a spiral manner. The spiral forming mold determines the diameter and thickness of the paper tube.

Cutting

After the paper tube is formed, the paper tube will be automatically cut to the set length by the cutting device. The cutting method includes automatic cutting and manual cutting, which depends on the machine type and demand.

Collection and stacking

The cut paper tubes will be transported to the collection device and neatly stacked for subsequent packaging or transportation.

Quality inspection

The produced paper tubes must be inspected manually or automatically to ensure that they meet the standard requirements such as diameter, length, thickness, etc.