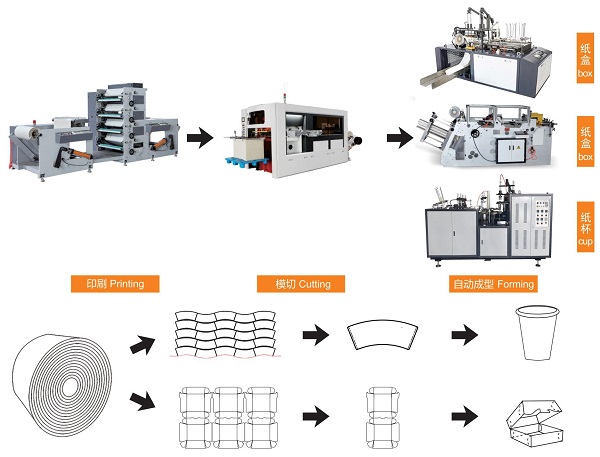

ZBNB-D Automatic paper cup handle machine is a new product which is designed and developed by our own company. The machine is an automatic forming machine with multi-running positions.

Whatsapp:

+8617838313982E-mail:

[email protected]ZBNB-D Automatic paper cup handle machine runs a whole procedure of paper-feeding, handle affix, cup-fan-wall sealing, oiling, bottom punching, heating, rolling, rimming, rounding, and tripping. The great advantage of the machine is making paper cup and handle into a whole.

| Type: | ZBNB-D |

| Cup size: | 3-12oz(different size mold exchanged) |

| Suitable paper material: | 150-300g/m2(single or double PE-coated paper) |

| Capacity: | 35-50pcs/min |

| Power source:: | 220V,380V 50HZ(please inform us your power in advanced) |

| Total power: | 4KW |

| Weight: | 1800KG |

| working power: | 6KW |

| Package size: | 2800 x 1400 x 1700 mm |

| Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min |

| A: top diameter:

Min 45mm—Max 90mm B: bottom diameter Min 35mm—Max 75mm C: total height Min 30mm—Max 115mm D: bottom knurling depth Min 4mm—Max 12mm E: rim diameter Usually Φ2.5—Φ3 |

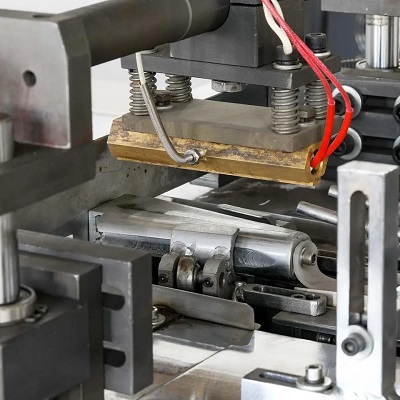

1. The Handle Cutting Mold: The cutting mold uses laser wooden mold, cheap and easily changed. The cutting board is flatter and lasts longer and is made of imported material.

2. Use a gear driving system instead of a chain, more stable for running and speeding up.

3. Use automatic lubrication recycle system instead of oiling by hand to reduce the friction and wear between gears, improve the machine safety and reduce the cost of maintenance.

4. We use 125 type gearbox, which is long life and more accurate. Normally,100 types of gearboxes are used.

5.100 type speed reducer is used instead of 80.

6. New design knurling wheel is used to guarantee even pressure and better bottom sealing.

7. ZBNB-D Automatic paper cup handle machine cup folding parts are controlled by three separate cams, and each folding clip can be adjusted by itself.

8. We use a manipulator to transfer the cup body instead of falling itself by pipe, It is more stable and accurate under fast running.

9. Organ type sucker is used for cup fan sucked to guarantee powerful sucking and more success. Life is much longer than a normal sucker.

If you need our products please write down any questions, we will reply as soon as possible.