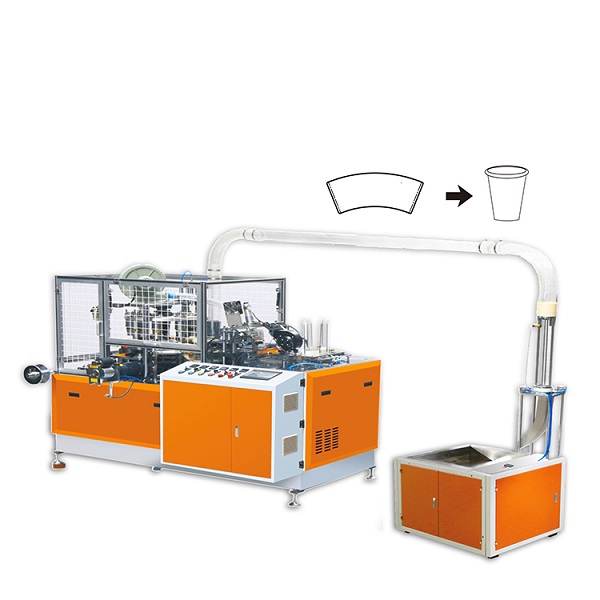

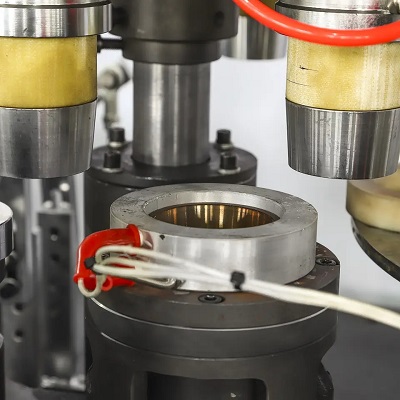

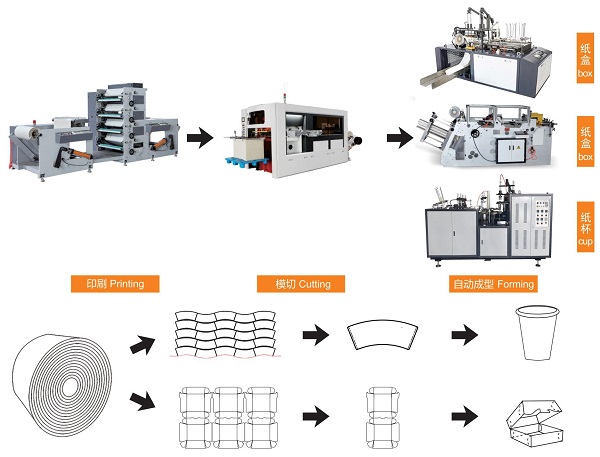

ZSZB-D automatic paper cup forming machine comes with an automatic lubrication system, which makes all mechanical parts work much more smoothly. The cup bottom adopts the stretching die which makes the bottom sealing quality better and less leaking percentage.

Whatsapp:

+8617838313982E-mail:

[email protected]ZSZB-D Automatic middle-speed paper cup forming machine has PLC control, a sensor failure detecting system, and cup bottom paper feeding controlled by a servo motor, the machine has a safety guard to protect the people working safely, and it is the best choice for making paper cups.

| Type: | ZSZB-D |

| Cup size: | 2.5-12oz(if the cup is more than 12oz,the machine designed more larger) |

| Suitable paper material: | (single or double PE-coated paper) |

| Capacity: | 60-90pcs/min |

| Power source:: | 380V 50HZ |

| Total power: | 8KW |

| Weight: | 2000KG |

| Package size: | 2200 x 1200 x 1700 mm |

| Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min |

| A: top diameter:

Min 45mm—Max 90mm B: bottom diameter Min 35mm—Max 75mm C: total height Min 30mm—Max 115mm D: bottom knurling depth Min 4mm—Max 12mm E: rim diameter Usually Φ2.5—Φ3 |

1. The capacity is increased to 60-70 cups per minute from 45-55 cups per minute.

2. Gear driving system is adopted instead of chain driving to avoid the chain loosed and broken.

3. ZSZB-D Automatic middle speed paper cup forming machine adopts a PLC system, HMI computer operation, and sensor detecting system. All of the electrical types of equipment use LG from Korea.

4. The machine host uses an automatic lubrication system. It is convenient to be well maintained and good for working life.

5. The bottom paper feeding is controlled by a stepping motor (or equipped with a servo motor) and sensor. The feeding length is adjusted quickly and accurately and reduces paper waste.

1. Machine Driving System: New design: Gear driving system. The previous design: Chain driving system

2. Main motor: ZSZB-D Automatic middle speed paper cup forming machine used the gear speed reducer instead of the gear reducer and the motor separated, simplified, and stable transmission system.

3. Bottom feeding: New design: bottom feeding is controlled by stepping-motor (or equipped with servo-motor) to guarantee quickly adjusted and accurate feeding. and sensor detection to control no cup tube no feeding. The previous design: bottom feeding is controlled by stepping-motor or unilateral bearing.

4. Operation System: New design: it adopts a PLC control system and HMI computer operation.The previous design: a machine operated by a switch.

5. The lubrication system: The new design: Adopts automatic lubrication and lubricant circuit.The previous design: manual lubrication.

| Motor | Main motor | (CHINA) |

| Knurling motor | (CHINA) | |

| Bottom feeding reduces motor | (CHINA) | |

| Bottom-feeding servo motor | SOYO (CHINA) | |

| Electric elements | HMI | (TAIWAN) |

| PLC | LG(KOREA) | |

| Frequency converter | LG(KOREA) | |

| All other electrical parts | LG(KOREA) | |

| Photoelectric switch | FOTEK(TAIWAN) | |

|

Pneumatic |

Solenoid valve and other parts | (CHINA) |

| main bearing | NSK | |

| Bearing | other bearings | (CHINA) |

If you need our products please write down any questions, we will reply as soon as possible.