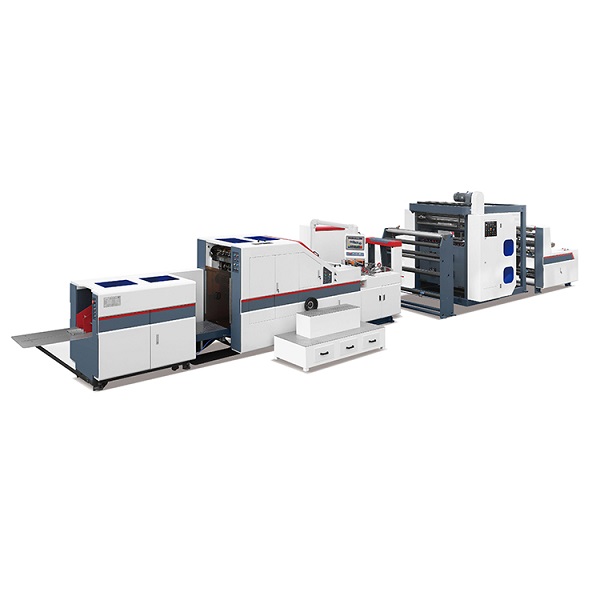

ZXFD-180/290/330/460 Square bottom paper bag machine with printing machine inline is suitable for varied primary and printed rolling paper, such as Kraft paper, slick paper, coated paper, medico paper, and so on. It finishes all procession all in a time consisting: of perforating, middle gluing, printed pattern calibration, tube forming, calibration snapping, bottom folding, bottom forming, and collecting the final product quantitatively.

Whatsapp:

+8617838313982E-mail:

[email protected]The ZXFD-180/290/330/460 square bottom paper bag making machine is used for raw color paper or printing roll paper such as kraft paper, food paper and other paper rolls. The machine can complete the square paper bag process at one time. It consists of automatic center gluing, printing bag tracking, raw material forming into tubes, cut-to-length, bottom creasing, bottom folding, bottom gluing, bag bottom forming, and finished bag finishing at one time.

This bag making machine is easy to operate, more efficient, and more stable. It is the equipment for producing various paper bags, snack food bags, bread bags, dried fruit bags and other environmentally friendly paper bags.

1. Cut with the point cutter.

2. It is suitable for paper between 60-150gsm.

3. We can control bag length through a human-machine interface.

4. ZXFD-180/290/330/460 Square bottom paper bag machine with printing machine inline the PLC system can calculate parameters correctly. It is equipped with an accurate photocell system.

| Model

|

ZXFD-180 | ZXFD-290 | ZXFD-330 | ZXFD-460 |

| Bag Length

|

191-371mm | 260-533mm | 260-533mm | 260-533mm |

| Bag width

|

80-190mm | 120-290mm | 140-330mm | 220-460mm |

| Bottom Size

|

50-100mm | 60-180mm | 60-180mm | 60-180mm |

| Paper Thickness | 50-120gsm | 60-150gsm | 60-150gsm | 60-150gsm |

| Max Roll width

|

320-600mm | 320-900mm | 320-900mm | 600-1300mm |

| Max Paper Roll Diameter | 1300mm | 1300mm | 1300mm | 1300mm |

| Material Core Diameter | 76mm | 76mm | 76mm | 76mm |

| Max Production Speed | 200pcs/min | 200pcs/min | 200pcs/min | 180pcs/min |

| Power | 19kw | 23kw | 23kw | 23kw |

| Weight | 5000kg | 8500kg | 9000kg | 10000kg |

| Machine Size(L*W*H) | 10000*1600*1750 mm | 11000*2500*1800 mm | 11000*2600*1800 mm | 11000*3000*1800 mm |

Conveying material

The automatic pneumatic device is adopted on the paper, and the manual switch on the paper is convenient without manual operation;

Paper bag forming

The whole bag tube is used to adjust the structure, so that it can be adjusted from one side or both sides, so that the design of the paper bag is simple and stable, thereby reducing adjustment time and unnecessary waste;

Bottom making

The length of the paper bag is controlled by a servo motor. Use a toothed knife to rotate at high speed and evenly to punch holes to ensure uniform and beautiful cuts, and use a durable rubber ring to punch holes with a long service life;

Finished product accepted

At the bottom of the glue structure, there is no glue tank type on the glue device, and the glue needs to be pulled upwards to stop glue quantitatively, so as to solve the problems of too much glue leakage and too long glue stop cleaning time;

If you need our products please write down any questions, we will reply as soon as possible.