Automatic Spiral Paper Core Making Machine For Potato Chips Tube

The Evolution of Potato Chip Paper Tubes: Sustainable Packaging Innovations

In the world of packaging, sustainability is not just a trend but a crucial paradigm shift. Among the innovative solutions emerging to reduce environmental impact, potato chip paper tubes have gained significant attention. These cylindrical containers not only preserve the crispy freshness of snacks but also contribute to the global effort towards eco-friendly packaging solutions.

Understanding Potato Chip Paper Tubes

Potato chip paper tubes are cylindrical containers made from sturdy paper materials. They are designed to replace traditional plastic packaging for snacks like potato chips, offering a more sustainable alternative. The tubes typically consist of several layers of paperboard or cardboard, providing robust protection for the contents inside while remaining lightweight and recyclable.

The construction of these tubes involves precise manufacturing processes. Key components include an inner liner for food safety and a sturdy outer layer for structural integrity. One of the critical technologies driving the production of these tubes is the Automatic Spiral Paper Core Making Machine . This machine plays a pivotal role in efficiently and consistently producing the cores around which the paper tubes are formed.

Paper Core Making Machine For Potato Chips Tube Advantages

Environmental Sustainability: Unlike traditional plastic packaging, potato chip paper tubes are biodegradable and recyclable. They help reduce plastic waste that litters landfills and oceans, making them a preferred choice for environmentally conscious consumers and businesses alike.

Preservation of Freshness: The design of these tubes ensures that snacks like potato chips retain their freshness and crispiness for an extended period. The inner liners protect against moisture and air, preserving the flavor and texture of the contents.

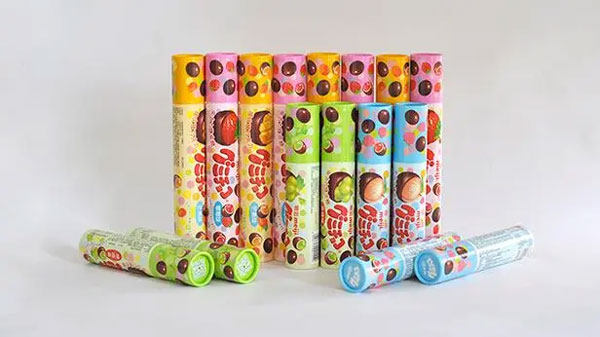

Versatility in Design: Potato chip paper tubes are highly customizable. They can be printed with vibrant designs and branding, making them attractive to consumers. The tubes also come in various sizes, accommodating different portions and packaging requirements.

Paper Core Making Machine For Potato Chips Tube Manufacturing Process

The production of potato chip paper tubes involves advanced manufacturing processes, including the use of the Automatic Spiral Paper Core Making Machine. This specialized equipment automates the core production process with precision and efficiency.

The Automatic Spiral Paper Core Making Machine for Potato Chips Tube operates by:

Spiral Winding: It utilizes spiral winding technology to wrap layers of paper around a mandrel, creating a sturdy core.

Gluing and Drying: Adhesive is applied between each layer of paper to ensure strong bonding, and the core is dried to achieve structural integrity.

Cutting and Finishing: Once the core is formed, it is cut to the desired length and undergoes finishing processes to prepare it for tube formation.

This automated approach not only enhances production efficiency but also ensures consistent quality and reliability in the manufacturing of potato chip paper tubes.

Paper Core Making Machine For Potato Chips Tube Future

Barrier Properties: Enhancing the inner liners of the tubes to improve barrier properties against moisture and oxygen, further extending shelf life.

Biodegradable Materials: Exploring biodegradable coatings and adhesives to enhance the recyclability and eco-friendliness of the tubes.

Smart Packaging: Integrating technologies such as QR codes or RFID tags for improved traceability and consumer engagement.

These innovations position potato chip paper tubes as a versatile and sustainable packaging solution poised to meet the demands of both consumers and regulatory standards.

Conclusion

Potato chip paper tubes represent a significant advancement in sustainable packaging solutions, offering benefits such as environmental sustainability, freshness preservation, and consumer appeal. Supported by technologies like the Automatic Spiral Paper Core Making Machine for Potato Chips Tube, these tubes are reshaping the packaging landscape in the food industry. As consumer awareness and regulatory pressures continue to drive the shift towards sustainability, potato chip paper tubes are set to play a pivotal role in the future of packaging innovation.