Daily maintenance skills of A4 paper crosscutting machine

We know that the old-fashioned cross-cutting machine equipment has only a one-meter wheel. Due to the large vibration of the cutter, the error of the length of the cut cardboard is also very large, and most of the errors are about 5 mm.

Currently, the latest A4 paper crosscutting machine technology uses two metering wheels. The traditional single meter wheel, that is, the meter wheel B is located in the front section of the cross-cutting machine and the rear section of the cross-cutting machine; while the double meter wheel is in the position of the meter wheel A, and another meter wheel is added.

Because, we generally use the meter wheel A, which basically does not vibrate at this position, and when the order is changed, the cardboard is cut, the meter wheel leaves the cardboard, and the knife shaft does not rotate. At this time, it is necessary to start the meter wheel B. position to measure, so use two measuring wheels for length measurement, which will be very accurate.

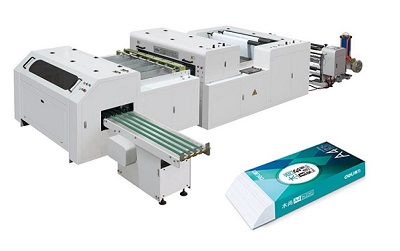

The main function of the A4 paper crosscutting machine

The A4 paper crosscutting machine consists of four parts: a measuring wheel, counterweight, sun wheel, and cutter shaft. The main function is to cut the running cardboard into a predetermined length.

1. The measuring wheel must be cleaned regularly to ensure that it is clean and free of debris. The motor cooling fan should be kept clean. If paper scraps are blocked, the motor will be easily damaged if the heat cannot be dissipated in time.

2. Check whether the blade is worn. If there is wear, adjust the gap, change the tool if necessary, and check whether the tool shaft is loose.

3. Check the transmission parts and fill in oil every two weeks; check whether the sun gear is clean and ensure that the pressures of the two sections are even and parallel.

Daily maintenance skills of A4 paper crosscutting machine

When using the A4 paper crosscutting machine, it is necessary to carry out regular maintenance, so as to ensure the smooth operation of the machine and the cutting quality of the product.

First, the A4 paper crosscutting machine should be installed in a dry, ventilated, well-lit place that is easy to operate.

Secondly, after each operation, it is necessary to clean up the dust and paper scraps on the machine in time, check the tool and the grinding wheel, check whether there is any abnormality in the running part, and add lubricating oil reasonably. Arrange the water in the oil-water high tank and the gas storage tank side by side.

Finally, after using the equipment, the user should cut off the power supply of the A4 paper crosscutting machine according to the operational requirements of the manual, and maintain the computer operating system.

The above is the basic daily maintenance work of the cross-cutting machine. The general principle is that the inspection, cleaning, and lubrication maintenance work is in place to ensure that all parts of the equipment are in good condition. In addition, it is also very important to improve the technical quality and level of operators. Special personnel should be responsible for the operation of the control part, and no one should operate it without permission.