How Are Paper Tubes Made?

Do You Know What a Paper Tube Is?

Paper tubes, sometimes called paperboard tubes, are cylindrical tubes made from wood pulp-based paperboard, kraft paper, fiberboard, and paper-glue composite materials. Paper tubes are made using a fully automatic paper tube making machine. The paper layers are laminated or bonded together using adhesives. The wall thickness of the tube can vary depending on the number of layers wrapped during the manufacturing process. Paper tube manufacturers first used them for storage of items, as protective shells, and as cores to wrap various materials and textiles around them. Today’s paper tubes are very strong and can be used for a variety of applications as manufacturing and design technology has advanced.

Fully Automatic Paper Tube Making Machine Operation Process:

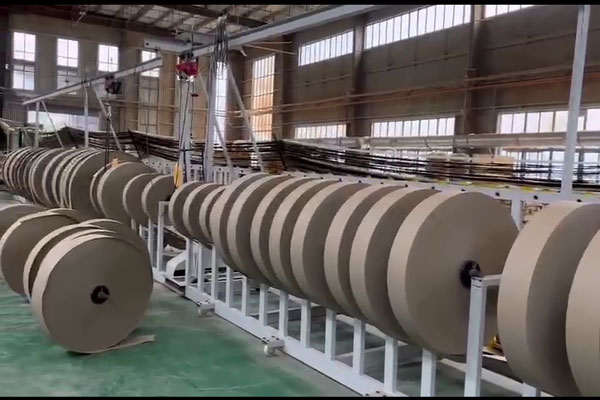

Step 1: Making ribbons from paper

The first step is to convert the recycled cardboard and lining materials into ribbons. They are then stacked together to form huge ribbon rolls that look like poker chips packed together. The thicker the tube you want, the more ribbon rolls you need.

Step 2: Gluing

The next step is to glue the paper tape together in an overlapping manner using industrial glue. Glue is applied between each layer to ensure that the paper retains its shape. This process is called a cascade gluing system. Any excess paper is scraped off and recycled.

Step 3: Winding the pile

Once the paper is well bonded, it is passed through a mandrel (a metal rod around which the paper is wound). The outer wheels of the mandrel can be adjusted to change the diameter of the paper tube. This process is called “winding”. It gives the paper tube a spherical shape.

Step 4: Cutting the paper tube

The last step is to cut the long wound of the paper tube into the precise predetermined size as required. After that, the tube is customized with decorative patterns and colored paper strips to meet the brand preferences of the customer.

Classification Of Fully Automatic Paper Tube Making Machine:

Spiral paper tube machine:

Spiral paper tube manufacturers wind them with the outer paper layer at an angle inclined relative to the axis of the tube. They have a high compressive strength and are ideal for packaging and shipping items such as cosmetics, food and medicines. They are also used for the safe delivery of frameless artwork and posters.

Parallel paper tube machine:

The outer edges of these tubes are wound at a ninety-degree angle and have high compressive and dynamic strength. They are mainly used in the construction process.

Pagoda Paper Tube Making Machine:

In the textile sector, pagoda paper tubes can be used to protect and support products such as yarn, fabric and sewing thread.

Application Areas Of Fully Automatic Paper Tube Making Machine:

For organic product packaging:

In an age where companies across industries are struggling to find ways to include natural ingredients in their products, it seems counterintuitive to sell these products in plastic containers. These paper tubes are made from recycled paper, so they fit in well with the company’s goals. You can change the specifications to better fit your product, and the look and feel can be customized to reflect your company’s identity.

For packaging hygiene products:

Branded personal hygiene products are often packaged in cardboard or paper tubes. Since most personal hygiene products are reusable, storing them in paper boxes is more beneficial to the brand because the paper tubes can be used over and over again.

For food packaging:

Paper tube packaging is becoming increasingly popular in the food industry as a way to promote the company’s commitment to using only natural and organic ingredients. It is completely safe to preserve, store and transport food in paper tubes. They can be made with extra layers designed to preserve food for longer.

Makeup and other cosmetics need packaging:

Elegant packaging is a common theme in the cosmetics and beauty industries. Each paper tube has a unique color, designed to let shoppers know that they are getting a different product than what they see on the shelf.

Tea Packaging:

Paper tube packaging has become standard for many popular tea brands. The container can be used multiple times, extending the life of the stored items. For example, to convey the relaxing effects of chamomile tea, you can use shades of blue, green, and yellow.

Dental Equipment Maintenance:

Not everyone is eager to learn more about available dental products. Offering a new line of packaging that stands out from the competition will help you win your customers’ attention.

Packaging Gifts:

One of the most frustrating aspects of receiving a gift is the uneven shape of the gift. When shipping fragile items, paper tubes can provide some cushioning and shock absorption, allowing the item to arrive at its destination intact.

For Clothing Packaging:

To save time on packaging, roll your clothing so that it does not wrinkle. However, heavier textiles can usually be unrolled without difficulty. This is why some clothing companies have begun shipping goods in paper tubes.

There are many specific cases for products that are suitable for paper tube packaging, such as umbrellas, towels, carpets, underwear, candles, kitchenware, etc. There are countless products that are suitable for paper tube packaging.