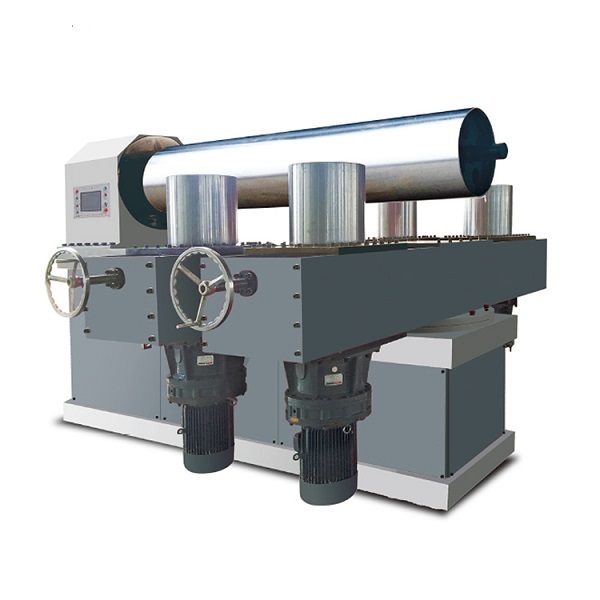

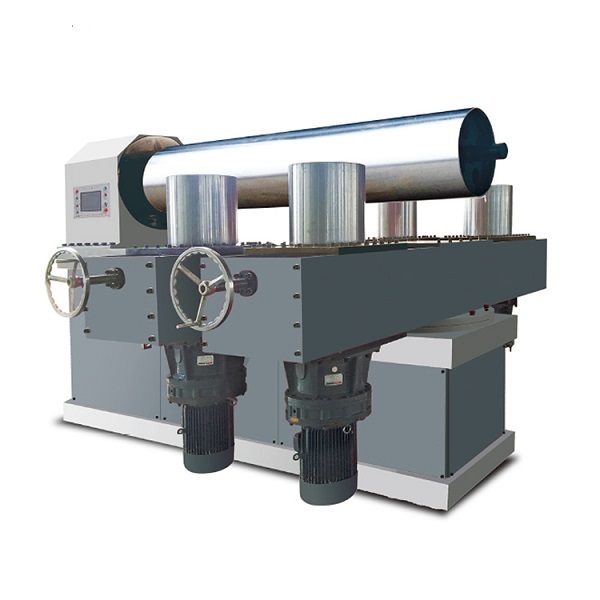

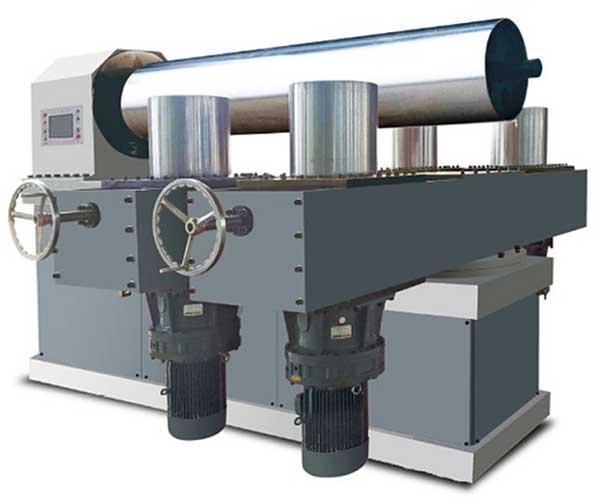

JYD-JG600B huge paper tube machine is mainly used for the production of large-mouth load-bearing paper tubes such as aluminum foil, steel strips, stainless steel plate, copper foil, and building formwork.

Whatsapp:

+86 17838313979E-mail:

[email protected]JYD-JG600B huge paper tube machine is mainly used for the production of large-mouth load-bearing paper tubes such as aluminum foil, steel strips, stainless steel plate, copper foil, and building formwork.

1. YD-JG600B huge paper tube machine the paper rack and gluing rack are integral electric moving devices;

2. The cutting table is cut by a servo synchronous high-speed saw, and is equipped with a dust recovery device;

3. The main huge paper tube machine is separated from the cutting table so that the glue sticking time is long and the strength of the paper tube is increased;

1. The mold fixing method of the main engine is flange fixing;

2. Independent transmission of four heads makes the machine more powerful;

3. According to different paper tubes, the coiling speed is between 0-3(m/min);

4. Suitable for the production of paper tube inner diameter Ф305-605mm; paper tube thickness 2-30mm;

5. By adjusting the foot plate at the bottom of the main machine to achieve horizontal stability of the machine;

6. The fixed-length mode of the paper tube is light-controlled fixed-length, which is simple and easy to operate, suitable for novices;

7. The motor of the cutting table is Shanghai Qiang Motor. This paper tube machine has low noise, strong power and low failure rate;

8. The synchronization of the cutting table is mechanical and pneumatic, and the return of the cutting table is completed by pneumatic;

9. The split structure of the cutting table and the main machine prolongs the bonding and cutting distance, which is beneficial to the bonding time of the paper tube.

10. The paper feeding cloth and paper frame device is made of iron plate wire cutting, which makes the arrangement of each layer of paper more uniform, thereby improving the flatness of the paper tube.

Here is our huge paper tube machine youtube video working process in our factory for your reference!!

| Technical parameter | |

| Number of paper layers | 5-52layers |

| Paper tube diameter | 305-605(mm) |

| The thickness of the pute | 2-30(mm) |

| Main power | 49.5KW |

| Input voltage | 380V/220V |

| Number of operators | 1-3 |

| Total weight | 11000kg |

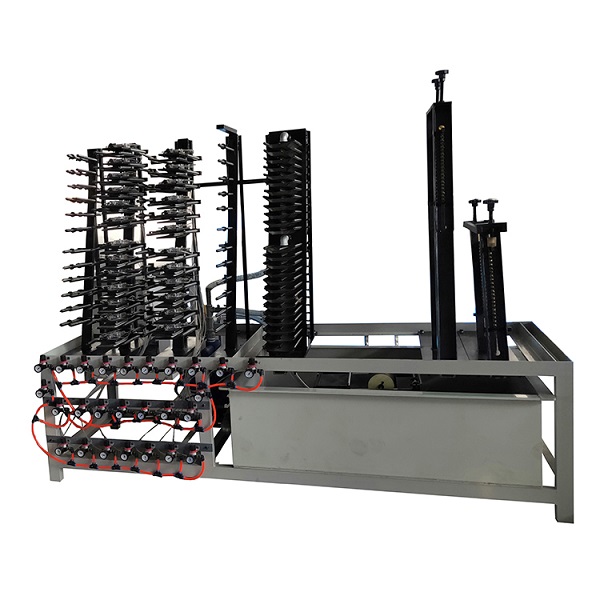

Mobile paper and glue rack

The upper paper frame and the glue frame are a joint movable hoisting paper frame and glue frame. This device is conducive to the rapid adjustment of paper tubes with different diameters.

Hoisting The paper on the upper paper rack is an electric double hoisting device, which makes paper loading faster. The paper rack shaft is a round steel shaft, which can make the paper run more smoothly. The paper rack can be adjusted by electric angle adjustment. The operation method is simple and economic artificial.

The hanging paper holder of the paper holder, humanized design holds the paper hanging holder with one hand, and operates the switch with one hand, so that one person can easily complete the lifting process.

The paper retaining plate on the paper holder shaft is made of high wear-resistant material and designed with high and low steps, which not only prevents the paper from moving left and right but also makes the paper roll run smoothly. Scroll movement increases fluency.

Bottom paper holder

The bottom paper frame is a one-time structure for bottom paper lubrication and gluing. .The automatic lubricating system of the backing paper is convenient, clean, easy to operate and evenly lubricated. The tension control of the backing paper controls the pressure of the air pressure plate by adjusting the pressure of the pneumatic valve to control the tension of the backing paper, so that the tension of the backing paper is balanced.

Unloading rack

The unloading frame is a three-cylinder lifting structure. After the paper tube is cut off, the paper tube is dropped to a lower place through the three-cylinder device, which saves manpower and is convenient for transportation.

If you need our products please write down any questions, we will reply as soon as possible.