Maintenance skills of JYD-JG60 Two-head CNC paper tube machine

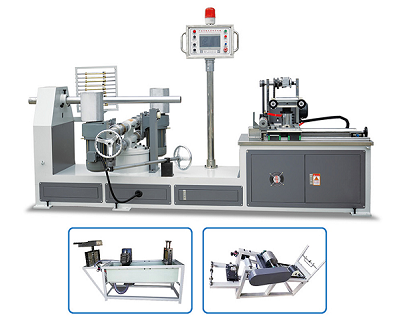

JYD-JG60 Two-head CNC paper tube machine not only has a wide range of categories but also has a wide range of applications, involving textile, chemical, printing and dyeing, papermaking, agricultural film, fireworks, food packaging, and other industries. This equipment is widely used in the market because it has many advantages at the same time, what are the advantages of the TSJG-60 Model paper tube machine?

Advantages of JYD-JG60 Two-head CNC paper tube machine

In real life, this high-speed multi-knife paper tube machine can perform automatic cutting operations. That is to say, the staff can operate the equipment at high speed only through computer control without manual operation. This way of working is not only safer and more reliable but also ensures the quality of products while ensuring the safety of operators. However, if it is to be manipulated, it needs to be implemented according to a specific specification.

When using the JYD-JG60 Two-head CNC paper tube machine, if there is a paper shortage problem, the machine will automatically stop working. This feature saves resources by preventing the device from doing too much work.

In contrast, this high-speed paper tube machine has sharp edges, so it can be formed in just one pass. This can improve production efficiency and reduce costs. For example, the plastic wrap used to wrap elevators is made using this equipment. During the operation of the paper tube machine, the staff should pay attention to the operation of the equipment and keep the equipment in good condition regularly.

Maintenance skills of JYD-JG60 Two-head CNC paper tube machine

JYD-JG60 Two-head CNC paper tube machine spindle speed change must be done after stopping. Gears are fully engaged when shifting. If the machine tool is found to be abnormal, stop immediately for an inspection

Before cutting, adjust the tool and clamp the workpiece. The parking baffle should be fixed, and the work can only be carried out after the sequence test of clamping, loosening, forward, and backward.

When the JYD-JG60 Two-head CNC paper tube machine is rotating, no part of the human body should contact the transmission parts. When operating, tie the cuffs, and it is strictly forbidden to wear gloves to work. The human head should deviate from the cutting direction.

JYD-JG60 Two-head CNC paper tube machine must be stopped when changing tools, measuring workpieces, lubricating, and cleaning tube heads. People should not stand in the direction of workpieces in and out.

JYD-JG60 Two-head CNC paper tube machine when cutting the tube head, it is necessary to prevent the tube head from flying out and hurting people. The dust removal device of the pipe-cutting machine should be in good condition before cutting.

When the long material pipe is put into the material rack and the lead wire is loosened, measures should be taken to prevent the pipe from rolling, impacting, and crushing people.

When using the grinding wheel pipe-cutting machine, you should check in advance whether the grinding wheel is damaged, cracked, or damp and whether the power cord is reliable.