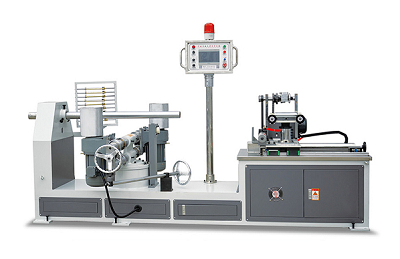

The development of the JYD-JG60 Two-head CNC paper tube machine

With the continuous development of technology, the current JYD-JG60 Two-head CNC paper tube machine not only has high working efficiency but also has the advantages of environmental protection and energy saving. Therefore, the use of JYD-JG60 Two-head CNC paper tube machines has become more and more extensive, and the types have become more and more abundant. In practical applications, the device also has excellent functions in terms of intelligence.

During the operation of this type of paper tube machinery, it is possible to wind a certain number of wide paper tapes to the required standard of inner diameter and wall thickness as required. The equipment has high power transmission efficiency, outstanding paper tube strength, and a lubricated appearance. In order to further improve the performance indicators of paper tube machinery, we can also achieve the purpose of energy saving by taking different measures.

For example, you can add a dedicated frequency converter that not only maintains stable operation but also saves power. Or it can enhance the maintenance function, such as adopting a full range of detection and maintenance functions, on the one hand, it can improve the safety function, and on the other hand, it can achieve the purpose of energy saving.

Frequency conversion technology is also used in the JYD-JG60 Two-head CNC paper tube machines. So, what impact does the frequency converter have on the energy-saving renovation of the equipment? In contrast, its low-frequency torque output is 180%, and the low-frequency running characteristics are excellent. Normally, the output frequency is 600Hz, which can control high-speed motors. Therefore, the paper tube machine has developed rapidly in terms of intelligence.

Assembly work of JYD-JG60 Two-head CNC paper tube machines

The assembly work of the JYD-JG60 Two-head CNC paper tube machines is usually divided into several assembly units that can be assembled:

1. Parts of JYD-JG60 Two-head CNC paper tube machines: It is the smaller unit that composes the paper tube machine and is made of a whole piece of metal or other materials.

2. Kit of JYD-JG60 Two-head CNC paper tube machines: It is composed of one or several parts installed on a reference part of the paper tube machine. It is the smaller assembly unit of the paper tube machine.

3. Components of JYD-JG60 Two-head CNC paper tube machines: It is composed of several kits and parts installed on the benchmark parts of the paper tube machine. For example, the spindle assembly.

4. Components of JYD-JG60 Two-head CNC paper tube machines: It is composed of several components, kits, and parts installed on the benchmark parts of the paper tube machine.

Three tips for overhauling

1. Visual inspection method. The operator directly observes the surface state of the paper tube machine to analyze the failure to see whether it runs smoothly and whether there is any abnormality.

2. Temperature detection method. Observe and check the temperature change of the paper tube machine, and use this as an information source to judge its operating status.

3. Noise detection method. Listen to the JYD-JG60 Two-head CNC paper tube machines for any abnormal sound when it is running. If it is found that the sound is not the same as usual, there may be a fault there.