The main function of the Two-head CNC paper tube machine

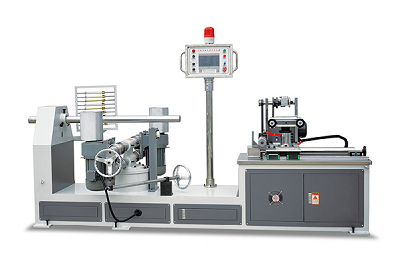

Paper tube machinery includes a number of equipment, which not only have a wide range of categories but also have a wide range of applications, covering textile, chemical fiber, printing and dyeing, papermaking, agricultural film, fireworks, and food packaging industries. The paper tube machinery we usually refer to includes not only spiral paper tube machines, flat roll paper tube machines, etc. related to paper tube production, but also tower paper tube machines, JYD-JG60 Two-head CNC paper tube machines, and paper tube machines. Hundreds of sets of equipment such as barrel machines. Let’s take the JYD-JG60 Two-head CNC paper tube machine as an example to explain the main function of the paper tube machine and the energy-saving transformation method.

Due to its excellent performance and good adaptability, the JYD-JG60 Two-head CNC paper tube machine is not only used more and more widely but also has more varieties. For example, this equipment can be used to process various chemical fiber industry pipes, various protective film products in the film industry, printing industry pipes, paper industry pipes, PU leather, real leather, carpet leather, etc. in the leather industry product.

In order to further improve the performance index of the JYD-JG60 Two-head CNC paper tube machine, we can also achieve the purpose of energy saving through different measures. For example, a dedicated frequency converter can be added, which can not only maintain stable operation but also save power. Or the protection function can be strengthened, such as the use of all-around detection and protection function, which can improve the safety performance on the one hand, and achieve the purpose of energy saving on the other hand.

Of course, we can also add corresponding acceleration, deceleration, and other protection functions to the JYD-JG60 Two-head CNC paper tube machine, which will also help to improve its performance. In addition, the performance of the motor can be improved with the automatic identification of dynamic parameters, thereby ensuring the stability and accuracy of the system.

In addition to the above measures, other methods can also be used to achieve energy-saving effects. For example, it can enrich the input and output interfaces and control methods of the paper tube machinery, or strengthen the quality management of each component to improve the overall stability of the equipment.

Main technical parameters of Two-head CNC paper tube machine

With the development of technology, the technical level of many paper tube equipment has been significantly improved. For example, the JYD-JG60 Two-head CNC paper tube machine adopts intelligent CNC unattended automatic glue spraying technology. In practical applications, the technology shows great advantages. From the analysis of the production situation, the diameter of its reel is 20 to 200 mm, and the number of layers of roll paper can reach 3 to 16 layers. Under normal operation, the speed of the coil can reach 3 to 16 meters per minute.

For users, this type of paper tube machine can process paper tube wall thicknesses ranging from 1 to 10 mm. The transmission mode used is chain transmission. The control forms use a multi-point operation panel and winding head.

Two heads and a single belt. In the process of operating the equipment, two to three staff members are generally required. The gluing method adopted by the equipment is fully CNC automatic gluing.

Comprehensive analysis, in fact, the JYD-JG60 Two-head CNC paper tube machine has many advantages, which is very important for the operator. For example, the device contains more than 80 function settings, and users can freely set the operation of the machine according to production needs. In addition, during the operation of the equipment, intelligent CNC unattended automatic glue spraying can be realized, which is not only efficient in operation but also has a high level of automation and is easy to operate.

During the operation of the JYD-JG60 Two-head CNC paper tube machine, not only can it maintain stable and reliable performance, but its operating noise is also very small, within 65 decibels. At the same time, the knives used are made of high-quality materials, which can ensure long service life. And the incision of the paper tube equipment is very flat and beautiful.