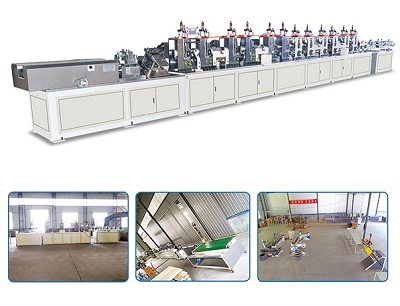

The operation process of the CNC U paper angle protector machine

JYD-U30 CNC U paper angle protector machine this production line can produce U profile edge protectors and paper flat. Automatic alarm system, supply of U-shaped paper corner protector, prompt fault location, safe operation. The conversion of the production line can be realized only by lifting the forming wheel pneumatically, installing the insert, and changing the position of the cutter. The price trend of paper edge protector machines in recent years has also been very stable. U profile paper edge protector machines can also be wholesaled in large quantities in the market, so manufacturers almost do the same in terms of price, but for the majority of people who want to purchase paper edge protector machines For machine companies, it is natural to hope that they can get a more favorable price. This is also a reasonable thing, so you need to prepare for these aspects when you choose the right one at the beginning.

Performance characteristics of CNC U paper angle protector machine

• Touch screen and high-power servo system man-machine interface to ensure accuracy and longevity;

•Using the characteristics of foreign pressure rollers, the corners of the paper are precisely shaped, and the glue will not be opened;

• Two-in-one gluing system, more flexible glue quantity control;

• Automatic alarm, fault prompt, more convenient maintenance.

1. The cutting is accurate, and the error is less than 0.5MM.

2. The cutting response is faster. When the production speed reaches 30 meters per minute, it can cut 200MM long paper corners, and when the production speed reaches 40 meters per minute, it can cut 300MM long paper corners. This is something hydraulic cutting can never achieve.

3. The failure rate is low. Due to the simple and scientific structure and the application of materials, the equipment failure rate is very low, and the maintenance is also quite simple.

4. JYD-U30 CNC U paper angle protector machine adopts an automatic stacking and counting line, the equipment can arbitrarily set the number of paper corner guards for each stack, and the equipment arranges the stacked paper guards neatly and conveniently for packing.

5. The improvement of the molding part makes the molding of the paper corner more stable and the fit is better.

6. The operation is easier, and the entire production line can be produced normally with only 2 people.

7. Fully digital operation, U profile paper edge protector machine, computer input of production specifications, production quantity monitoring, and large-size display screen display.

The operation process of the CNC U paper angle protector machine

1. Adjust the height and feed of the cutting table according to the diameter of the production paper tube, and adjust the position of the photoelectric switch for length measurement according to the length of the paper tube.

2. The paper enters the gluing part and the scraping part through the feeding part of the glue pool of the U profile paper edge protector machine. Pay attention to the same position of the paper before and after. Before scraping the paper, manually apply glue to increase lubrication, so as to prevent the paper from being broken due to excessive tension on the paper.

3. JYD-U30 CNC U paper angle protector machine the paper enters the main machine through the cloth paper holder of the main machine. Before that, wrap the bottom paper around the mold shaft. At this point, turn the first set of handwheels to tighten the belt. When the paper passes through the second set of belts, turn the second set of belt-tightening handwheels to tighten the belt.

4. During the production process, personnel should always pay attention to the adhesion of the glue, check whether the paper tube is suitable, and whether there is any paper breakage.