Kraft Paper Tube Manufacturing Process

Kraft paper is brownish-yellow, and its main features are flexibility and firmness, high burst resistance, and it can withstand large tension and pressure without breaking. It is often used to make kraft paper tubes, because kraft paper itself has good paper strength, which in turn ensures that the surface of kraft paper tubes is smooth and flat, bright in color, tough and pressure-resistant.

The specific manufacturing process of kraft paper tube is as follows:

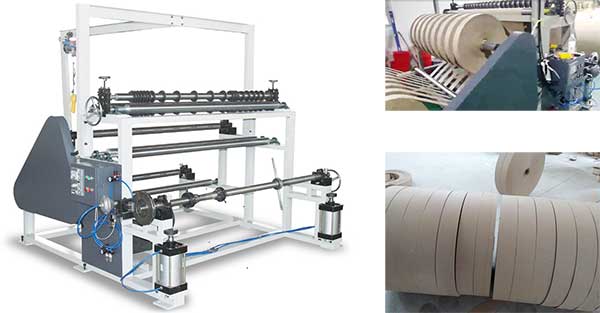

1. Data paper cutting: pay attention to the sand tube paper with uniform thickness, low moisture content and smooth surface as the main paper, and use impregnated paper as the surface paper; The large roll of surface paper is placed in the paper slitting machine for slitting, and the paper tape of the required size is obtained;

2. Rolling tube: the glued paper tape is wound into a tube on a professional kraft paper tube machine;

Here is the kraft paper tube making machine youtube video working process in our factory for your reference!!

3. Rough cutting: Put the kraft paper tube on the resin-coated paper tube and pass it through the air dryer at a constant speed, and then cut it into a certain length of paper tube section by the paper tube rough cutter;

4. Fine cutting: roughly cut the extruded kraft paper tube according to the required size, chamfer the end face of the kraft paper tube after cutting, coat and pack, and then complete the kraft paper tube manufacture with seamless surface;

5. Paper tube drying: Put the kraft paper tube section roughly cut into sections to dry in the drying room until the water content of the kraft paper tube is lower than 10%;

6. Paper tape gluing: Put several layers of main paper tapes and surface paper tapes processed by grooves in sequence from top to bottom layer by layer dislocation and stacking rules, and put them in parallel on the paper tape gluing machine. Evenly coat a layer of paper tube special glue with the upper surface of the surface paper tape;

7. Extrusion molding: After the dried kraft paper tube sections are arranged and cooled to room temperature, put them one by one into a molding die that has been preheated to a temperature of 150-280C for internal extrusion molding, so that the outer surface of the kraft paper tube has been coated with resin fully cured: the molding temperature of the mold is 150- 280C;

8. Groove detail processing: put the surface paper tape into the beveling machine to perform groove detail processing on both sides of the paper tape;

If you also want to start a kraft paper tube manufacturing business, or if you have any questions about kraft paper tube manufacturing, please feel free to leave a message with us online to get more detailed information and free quotations about kraft paper tube machine!